Table of contents:

Total Cost of Ownership: Comparing FK3 to Traditional Outdoor Lighting Options

Energy Efficiency Metrics: Understanding Lumens Per Watt in LED Flood Lighting

Installation and Maintenance Savings with Modern Outdoor LED Fixtures

How Quality Outdoor Flood Lighting Impacts Customer Experience and Sales

Total Cost of Ownership: Comparing FK3 to Traditional Outdoor Lighting Options

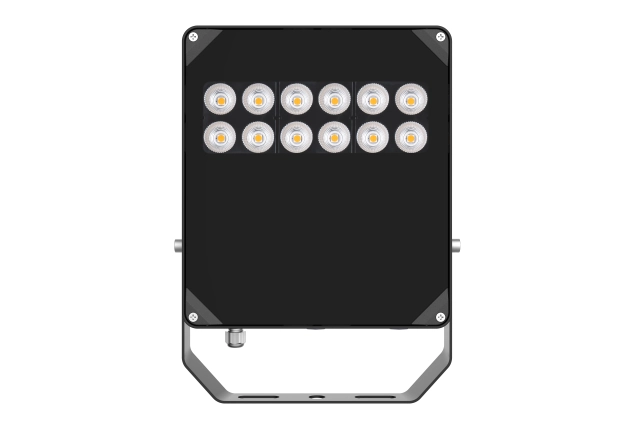

When evaluating lighting options, it's essential to look beyond the initial purchase price and consider the total cost of ownership. The FK3 LED Flood Light 50W stands out as a cost-effective choice compared to traditional lighting systems. Its high-efficiency LED light source significantly reduces energy consumption, translating to lower electricity bills over time. Moreover, the durability and longevity of LED technology mean fewer replacements and less frequent maintenance, further reducing long-term costs. These industrial LED lighting solutions offer a compelling financial advantage, making them an attractive option for businesses looking to optimize their outdoor lighting expenditure while maintaining high-quality illumination.

Energy Efficiency Metrics: Understanding Lumens Per Watt in LED Flood Lighting

One of the key metrics in assessing the efficiency of outdoor lighting solutions is lumens per watt (LPW). This measure indicates how much light output is produced for each watt of electricity consumed. The FK3 LED Flood Light 50W excels in this area, offering superior LPW compared to traditional lighting options. This high efficiency not only contributes to energy savings but also aligns with sustainability goals, an increasingly important factor for many businesses. By choosing these advanced industrial LED lighting solutions, companies can demonstrate their commitment to environmental responsibility while enjoying the benefits of reduced energy costs.

Installation and Maintenance Savings with Modern Outdoor LED Fixtures

The FK3 LED Flood Light 50W is designed with ease of installation and minimal maintenance in mind, factors that contribute significantly to its overall cost-effectiveness. Its IP66 protection rating ensures durability in various outdoor environments, reducing the need for frequent replacements due to weather-related damage. The fixture's double breathing valves technology adjusts air pressure and prevents water and fog ingress, further extending its lifespan. These features of modern outdoor lighting solutions, such as energy-efficient designs, durable materials, and longer-lasting technology, translate to fewer man-hours spent on maintenance and replacement. This not only reduces operational costs but also allows businesses to allocate resources more efficiently, focusing on other critical areas like improving customer experiences or enhancing overall infrastructure.

How Quality Outdoor Flood Lighting Impacts Customer Experience and Sales

Beyond the operational benefits, investing in high-quality outdoor lighting solutions can have a direct impact on customer experience and, consequently, sales. The FK3 LED Flood Light 50W's reflector design ensures accurate light distribution, effectively reducing light pollution while providing optimal illumination. This precision in lighting can enhance the visual appeal of business premises, create a safer environment for customers and employees, and potentially extend operational hours. For retail businesses, in particular, well-designed outdoor lighting can increase foot traffic and create an inviting atmosphere that encourages longer customer stays and higher sales.

In conclusion, the FK3 LED Flood Light 50W represents a smart investment in industrial LED lighting solutions that can yield significant returns for businesses. By reducing energy consumption, minimizing maintenance costs, and enhancing the overall customer experience, these advanced outdoor lighting solutions offer a compelling value proposition. As companies increasingly focus on operational efficiency and sustainability, the adoption of such innovative lighting technologies becomes not just a choice, but a strategic necessity. The FK3 LED Flood Light 50W stands out as a reliable and efficient option in the competitive landscape of outdoor lighting solutions, promising long-term benefits that extend far beyond simple illumination.