Table of contents:

Role of Precise Position Detection in Elevator System Safety

High-Precision Internals Resisting Vibration and Dust Exposure

Modular Design Features Enabling Diverse Actuator Compatibility

Role of Precise Position Detection in Elevator System Safety

Precise position detection acts as the conductor that ensures every elevator movement is safe and accurate. This isn't just about stopping at the right floor; it's about how the system understands its own location within the shaft at all times. A limit switch acts as a definitive checkpoint, sending a crucial signal to the control panel when the car reaches a predetermined point, such as the top or bottom of its travel range. Without this precise feedback, the system could fail to decelerate correctly, leading to unsafe over-travel conditions. The Precision Positioning Limit Switch from Ningbo Ruilin Technology Co., Ltd is engineered specifically for this purpose. It provides consistent and reliable mechanical feedback, ensuring that the triggering is exact every single time. This level of dependability is non-negotiable for maintenance professionals who rely on high-quality elevator spare parts to maintain system safety. Sourcing components from reputable elevator parts suppliers ensures that this fundamental safety layer, which prevents dangerous operational failures, is built on a foundation of reliability and precision engineering. This switch's ability to support precise position detection is essential for maintaining the integrity and safety of the entire elevator operation.

High-Precision Internals Resisting Vibration and Dust Exposure

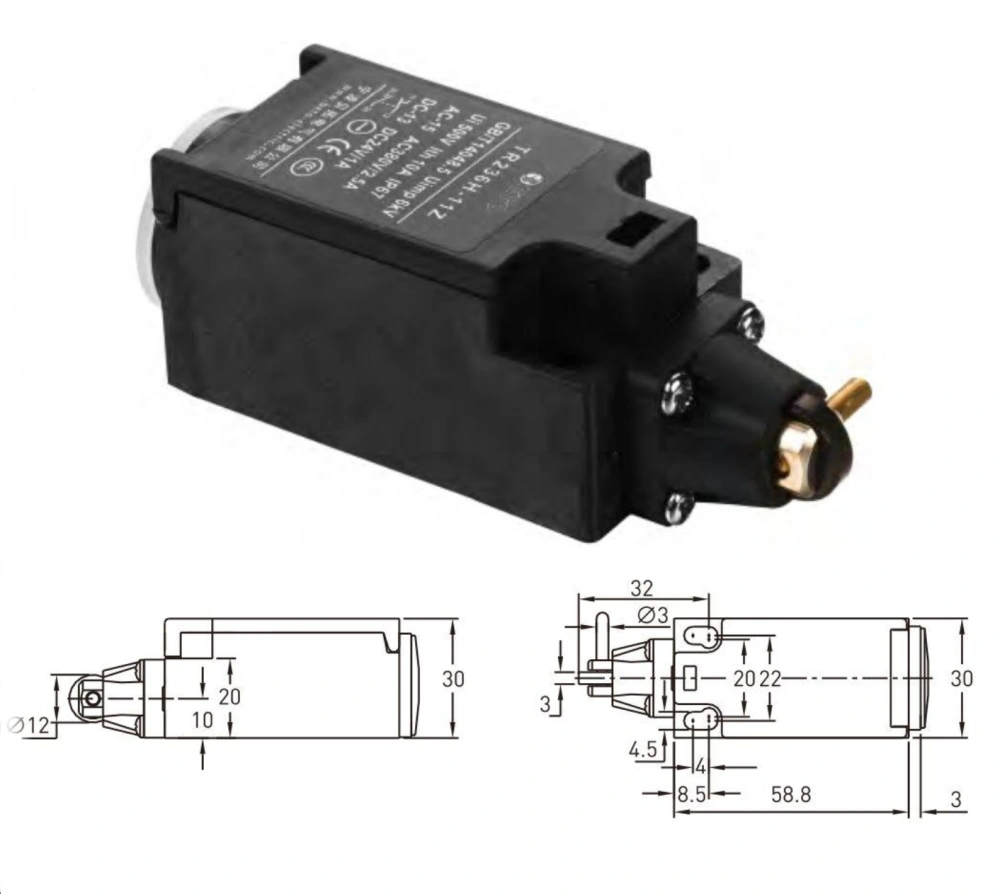

Elevator shafts pose a demanding industrial environment, characterized by constant motion, mechanical vibration, and the inevitable accumulation of dust and debris. These factors pose a significant threat to the longevity and reliability of sensitive electronic components. A standard switch might falter under such conditions, leading to inconsistent performance or premature failure, which is a major concern for building maintenance. This is why the internal construction of a limit switch is so critical. The Precision Positioning Limit Switch addresses these challenges with high-precision internals specifically designed to withstand these environmental stressors. Its components are shielded against dust exposure and engineered to operate consistently despite temperature variations and persistent vibrations. Furthermore, its reinforced arm construction, featuring durable metal limit switch arms, is built for long-lasting performance, capable of enduring thousands of activation cycles without degradation. For elevator parts suppliers, offering components that promise this level of resilience is key. Technicians need elevator spare parts that won't require frequent replacement, reducing downtime and ensuring the long-term safety of the system. This focus on durability makes the switch a trusted, professional-grade solution for demanding applications.

Modular Design Features Enabling Diverse Actuator Compatibility

Maintenance technicians and engineers must prioritize efficiency as much as reliability. When a critical component needs replacement, the process should be as straightforward as possible to minimize elevator downtime. This is where modularity and compatibility become incredibly valuable. A component designed with a universal fit can be a lifesaver, eliminating the need to source a highly specific part for a particular system. The Precision Positioning Limit Switch excels in this area due to its thoughtful modular design. It is engineered to be compatible with a variety of limit switch actuators, making it a versatile choice for many different elevator models and configurations. This adaptability simplifies the inventory management for elevator parts suppliers, who can offer a single, reliable solution that meets diverse needs. For the technician on site, this means a simplified installation process. The switch integrates easily into standard control systems without the need for complex modifications, which directly translates to reduced service time and faster restoration of the elevator's operation. By providing a flexible and easy-to-install solution, this switch helps streamline maintenance workflows while ensuring that the core safety functions are upheld with dependable elevator spare parts.

Ensuring elevator safety comes down to the quality and reliability of each individual component. A limit switch that combines precision, durability, and easy integration is not just a convenience but a necessity. For elevator parts suppliers and maintenance teams, having access to dependable elevator spare parts is crucial for upholding safety standards. The Precision Positioning Limit Switch, with its durable metal arms and robust internals, provides that assurance.

No comments:

Post a Comment