Table of contents:

Designing Long-Life Dies with Reinforcements for High-Cycle Industrial Use

Integration of Real-Time Feedback Loops in Die Adjustment and Pilot Production

Role of Material Selection and Construction Techniques in Automotive Stamping Dies

Designing Long-Life Dies with Reinforcements for High-Cycle Industrial Use

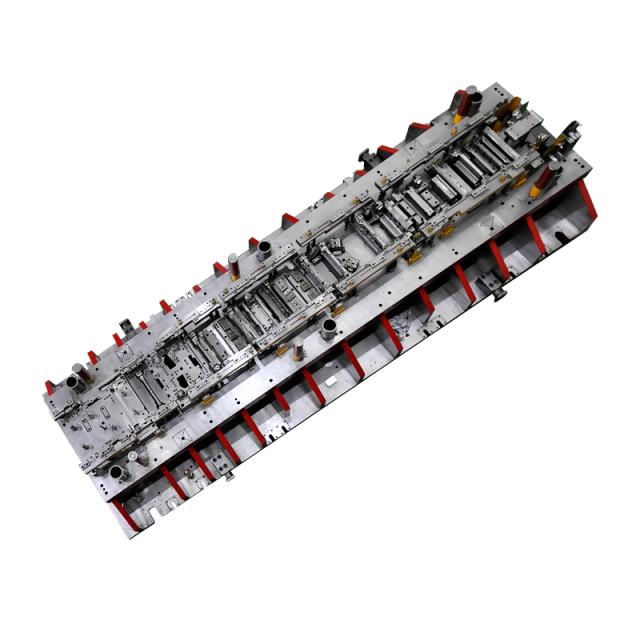

The longevity of a stamping die is fundamental to maintaining production efficiency and cost-effectiveness in automotive manufacturing. Dies subjected to repeated high-pressure impacts can experience wear, dimensional drift, or even catastrophic failure, halting production. To counter this, a forward-thinking metal stamping dies manufacturer focuses on building durability into the core design. ZYLY constructs its custom metal stamping dies from high-grade hardened tool steels, which provide a robust foundation capable of withstanding the intense forces of high-volume stamping. Beyond the base material, critical areas of the die are fitted with wear-resistant components and structural reinforcements. This approach is particularly important for producing complex automotive hardware like mounting brackets, where intricate shapes must be held to tight tolerances. The design also incorporates replaceable components, a practical feature that allows for quick maintenance and minimizes downtime. Instead of replacing an entire die set, technicians can swap out worn parts, extending the overall operational life of the tooling. This focus on high cycle life ensures that the custom metal stamping dies can sustain continuous operation under demanding press conditions, delivering consistent part quality from the first part to the millionth.

Integration of Real-Time Feedback Loops in Die Adjustment and Pilot Production

Achieving seamless coordination between tooling geometry and stamping parameters is essential for efficient production. A vertically integrated process, where die design, manufacturing, and stamping are managed in-house, creates a powerful advantage. This tight control, a hallmark of ZYLY's operations, enables the establishment of real-time feedback loops. During pilot production for a new vehicle component, initial stamped parts are immediately evaluated for dimensional accuracy and form quality. Any deviations are fed back to the tooling department, allowing for rapid adjustments to the die. This streamlined communication eliminates the lengthy and often frustrating trial-and-error cycles that occur when working with separate vendors. The ability to quickly adapt custom metal stamping dies is invaluable when developing parts for new models or implementing component changes. It facilitates faster pilot runs and allows for flexible scaling to full production. With a facility supporting presses from 40 to 400 tons, this integrated system ensures that the custom metal stamping process is stable, repeatable, and capable of producing over 500,000 parts monthly with remarkable batch-to-batch consistency.

Role of Material Selection and Construction Techniques in Automotive Stamping Dies

The quality of a stamped automotive part is a direct reflection of the die that formed it, and the die's performance hinges on its material composition and construction. The choice of materials is not a one-size-fits-all decision; it requires deep expertise in metallurgy and stamping dynamics. A skilled metal stamping dies manufacturer like ZYLY, with over 15 years of experience, carefully selects specific grades of hardened tool steels based on the application's demands, such as the type of metal being stamped and the complexity of the part geometry. The construction process is equally critical. ZYLY utilizes optimized die structures that manage material flow and stamping sequences to minimize unwanted deformation, springback, and stress concentrations. This meticulous approach to creating custom metal stamping dies ensures that parts like chassis reinforcements and mounting components are produced with precise shape control and dimensional consistency. Adherence to ISO 9001:2015 quality standards throughout the CAD design, simulation, and manufacturing stages further guarantees that each of the 300–400 die sets produced annually is built for reliability, durability, and the smooth final assembly of automotive hardware.

This integrated approach, from die design to final custom metal stamping, is key to delivering dependable automotive components. By focusing on durable materials, intelligent design, and a responsive production cycle, manufacturers can ensure every part meets stringent quality requirements. ZYLY's commitment to precise shape control and durability in its custom forming dies provides automotive partners with the confidence of repeatable quality. For brands seeking a reliable metal stamping dies manufacturer that aligns tooling and stamping for process stability, exploring a vertically integrated partner is a step toward more efficient and consistent production.

No comments:

Post a Comment